Choosing the right type of wire for your fence is the first step in the process of securing your area with a fence. Wires before they are used for manufacturing chain link fence, undergo galvanization process, a technique in which zinc coating is added to prolong its life and enhance its quality.

Primarily there are 2 types of Galvanizing processes when we talk about wire for Chain Link Fencing: Hot Dipped Galvanizing and Cold Galvanizing

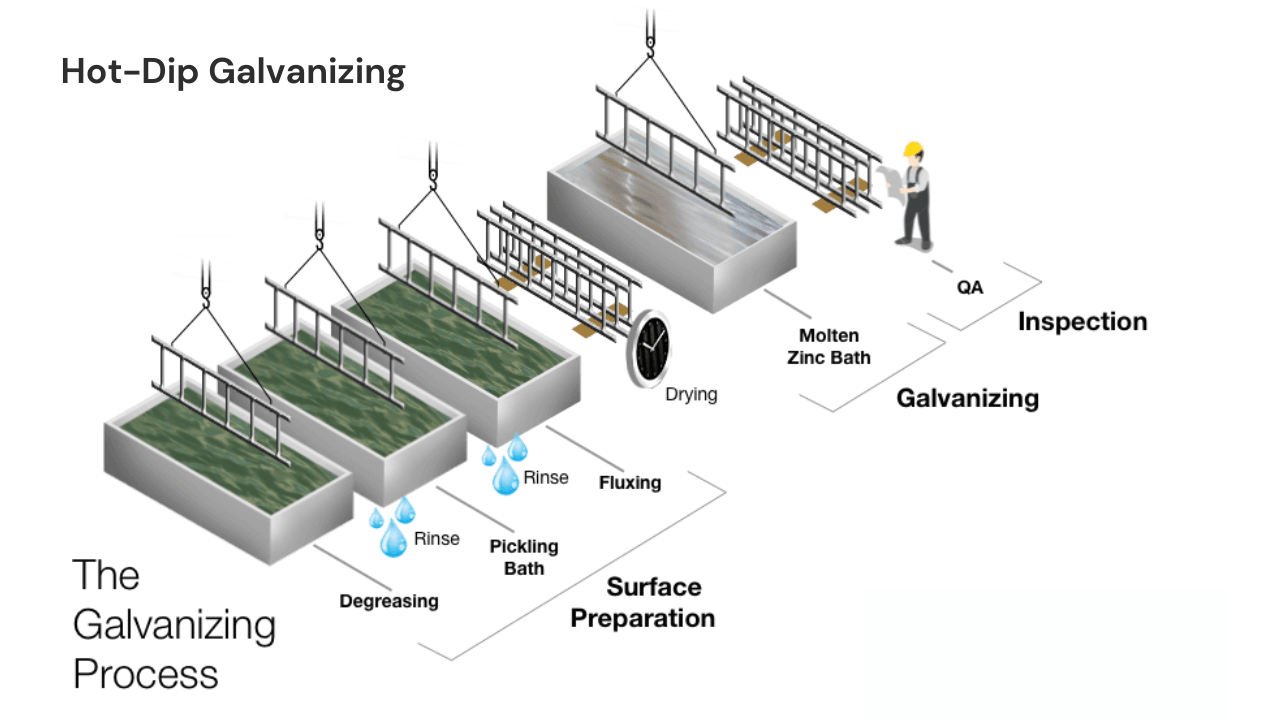

Hot Dipped Galvanizing

Hot Dipped Galvanizing is a process in which wire is dipped in molten zinc and the range of coating possible in this technique is as low as 45 Micron and as high as 300 Micron. When raw wire is dipped in molten zinc at high temperature, it undergoes a number of chemical reactions and the surface of wire coated with high quality zinc.

Cold Galvanizing

In this technique, wire is placed in already prepared zinc solution. Later using the principles of electrolyte, zinc coating is layered onto the wire.

Difference in both Techniques:

Thickness of Coating

It is important to know that the results of both above techniques are different – The thickness of zinc coating in Cold Galvanizing is thinner than that of Hot Dipped Galvanizing and hence the later is able to withstand corrosion and rusting more than the primary technique. Eventually Hot Dipped Galvanized Chain Link Fencing has more life and durability.

Colour

Both Cold and Hot Dipped galvanizing results in silvery white finish to the wire. However, cold galvanized wire and fences are brighter in finish and hot dipped galvanized wire and fences have matt finish.

Advantages of Hot Dipped Galvanized Wire and Fences:

- Lower production costs as compared to regular coating.

- Reliable in nature due to heavy coating on the wire.

- Hot Dipped Galvanizing ensures the fence can withstand mechanical damage and hence toughness of this type of fence is more.

- Each part of the fence, be it small corners or bends can be coated perfectly and hence this technique ensures complete protection.

Conclusion

Hot Dipped Galvanized technique is definitely a better choice for making wire and fence as it can offer more life span and better quality. At Al Miqat Fencing Factory, all our wires are coated with Hot Dipped Galvanizing coating to ensure our finished products are of high quality and durability.Top of Form